Suppressing thermal emission loss—also regarded as blackbody radiation—while concurrently absorbing photo voltaic gentle is crucial for an economical photo voltaic thermal absorber but is really demanding to reach, claims Baohua Jia, founding director of CTAM. “That’s due to the fact, relying on the absorbed warmth and houses of the absorber, the emission temperature differs, which prospects to significant distinctions in its wavelength,” she explains. “But we have designed a three-dimensional structured graphene metamaterial (SGM) that is really absorbent and selectively filters out blackbody radiation.”

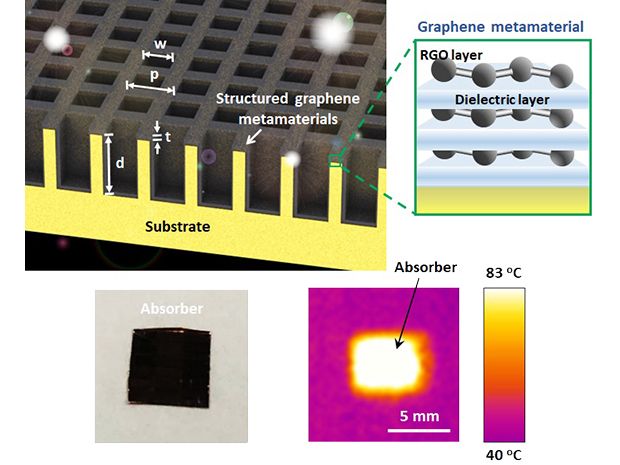

The 3D SGM is composed of a thirty-nanometer-thick movie of alternating graphene and dielectric levels deposited on a trench-like nanostructure that does double responsibility as a copper substrate to greatly enhance absorption. A lot more importantly, the substrate is patterned in a matrix arrangement to help versatile tunability of wavelength-selective absorption.

The graphene movie is designed to take up gentle amongst .28- to two.five-micrometer wavelengths. And the copper substrate is structured so that it can act as a selective bandpass filter that suppresses the regular emission of internally created blackbody electrical power. This retained warmth then serves to further elevate the metamaterial’s temperature. Hence, the SGM can quickly warmth up to eighty three degrees C. Need to a various temperature be needed for a individual application, a new trench nanostructure can be fabricated and tuned to match that particular blackbody wavelength.

“In our past operate, we shown a ninety nm graphene warmth-absorbing material,” claims Baohua. Although it could warmth up to a hundred and sixty degrees C, “the framework was much more intricate, [comprising] 4 levels: a substrate, a silver layer, a layer of silicon oxide, and a graphene layer. Our new two-layer framework is simpler and does not require vacuum deposition. And the method of fabrication is scalable and very low expense.”

The new material also uses less graphene by considerably cutting down the movie thickness to just one 3rd, and its thinness aids in transferring the absorbed warmth much more efficiently to other media this sort of as h2o. In addition, the movie is hydrophobic, which fosters self-cleansing, even though the graphene layer properly guards the copper layer from corrosion, assisting to prolong the metamaterial’s life time.

“Because the metal substrate’s structural parameters are the primary aspects governing general absorption performance of the SGM, somewhat than its intrinsic capabilities, various metals can be utilized in accordance to application demands or expense,” claims Keng-Te Lin, lead creator of a paper on the metamaterial just lately printed in Character Communications, and who is also a study fellow at Swinburne College. Aluminum foil can also be utilized to change copper without the need of compromising the performance, he notes.

To check the metamaterial’s style and design and security, the scientists fabricated a prototype employing regular laser nanofabrication, self-assembly graphene oxide coating, and image-induced reduction.

“We utilized the prototype movie to create clean h2o and accomplished an remarkable photo voltaic-to-vapor efficiency of ninety six.two {36a394957233d72e39ae9c6059652940c987f134ee85c6741bc5f1e7246491e6},” claims Keng-Te. “This is quite aggressive for clean h2o technology employing a renewable electrical power source.”

He adds that the metamaterial can also be utilized for electrical power harvesting and conversion apps, steam technology, wastewater cleansing, seawater desalination, and thermoelectricity technology.

A single obstacle continue to remaining is finding a producing method for creating the substrate scalable.

“We are functioning with a private corporation, Innofocus Photonics Technological know-how, that has commercialized a coating machine to lay down the graphene and dielectric levels,” claims Baohua. “And we are content with that. What we are now searching for is a appropriate method for huge scale output of the copper substrate.” A single risk, she adds, is employing a roll-to-roll procedure.

In the meantime, the scientists are continuing to fine-tune the nanostructure style and design and strengthen the SGM’s security and absorption efficiency. “As for commercialization,” claims Baohua, “we consider that will be probable in just one to two many years.”